Marley machining features

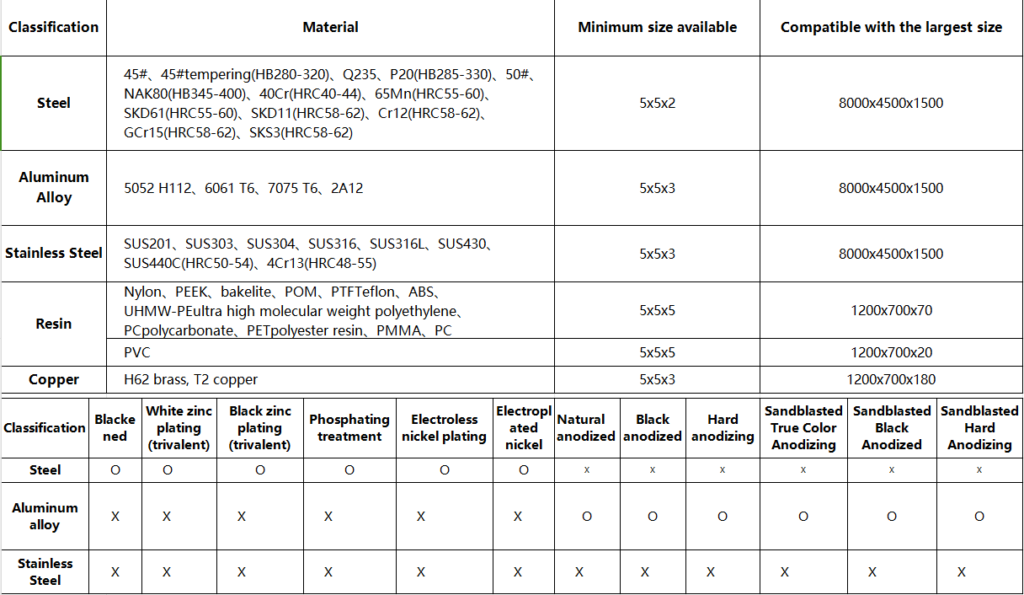

Corresponds to most mainstream materials and surface treatments, meeting parts needs in various scenarios

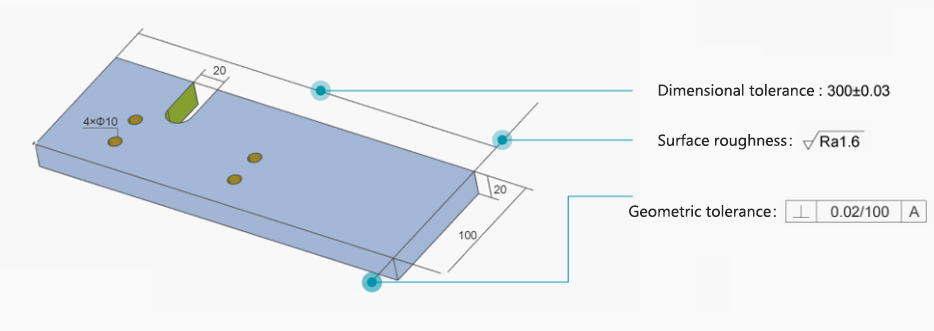

Freely define dimensional tolerances, surface roughness and geometric tolerances

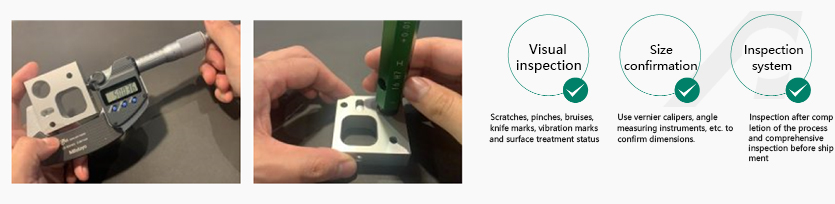

Marley QA benchmark, strict quality control

Marley is committed to providing users with “QCT” services to help enterprises reduce costs and increase efficiency.

Quality+Cost+Time

Marley sheet metal parts production examples

Name: Motor Bracket

Dimensions: L240xW110 xH10mm

Details: Q235/blackening treatment

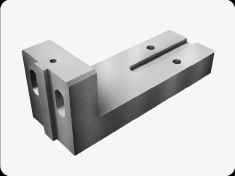

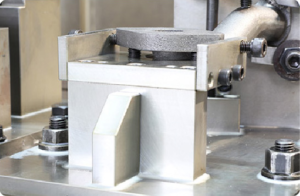

Name:L-shaped positioning block

Name:L-shaped positioning block

Dimensions: L145xW56 xH50mm

Details: 5052 H112

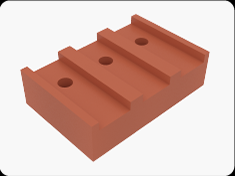

Name: Basic Block

Name: Basic Block

Size: L90 xW60xH25mm

Details: Bakelite (orange-red)

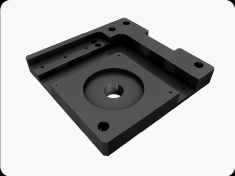

Name: Basic Block

Size: L150xW150 xH20mm

Details: 6061 T6 / black anodized

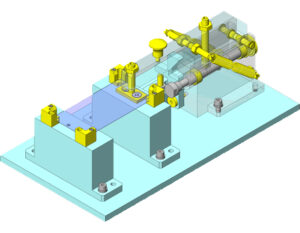

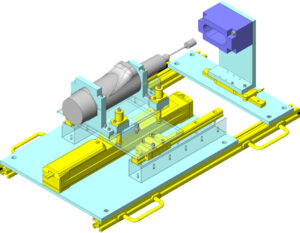

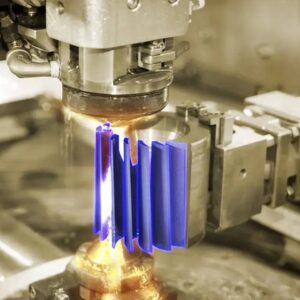

Application of Marley in institutions or equipment

Semi-automatic grinding device Marley parts coverage 93%

Low impact, fixed force manual clamping mechanism Marley parts coverage 92%

Marley’s application in equipment

Automobiles, electronics, medical care, robots, AGV, etc.

Various production equipment and inspection equipment

+ direction detector

+ conveyor mechanism

+ cutting device

Fixtures on production lines and general machine tools

Fixtures on production lines and general machine tools

+ Turntable fixing parts of conveyor device

+ Height adjustment parts for welding fixtures

+ CNC adjustment plate

Reviews

There are no reviews yet.