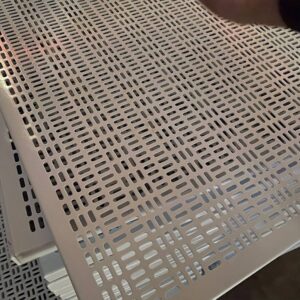

Heat Exchanger Tube Product Details

| Attribute | Details |

| Product Name | Heat Exchanger Tube |

| Material | Stainless Steel, Carbon Steel, Copper, Titanium, Nickel Alloys |

| Standards | ASTM, ASME, DIN, EN, JIS |

| Outer Diameter | 6mm – 219mm |

| Wall Thickness | 0.5mm – 20mm |

| Length | Customizable, typically 1m – 12m |

| Surface Finish | Annealed, Pickled, Polished, Passivated |

| Applications | HVAC systems, Power plants, Chemical processing, Oil & Gas, Marine, Pharmaceutical, Food & Beverage |

| Features | High thermal conductivity, Corrosion resistance, Pressure resistance, Durability |

| Manufacturing Process | Seamless, Welded, U-bent, Fin Tube |

| Testing & Inspection | Hydrostatic test, Eddy current test, Ultrasonic test, Visual inspection |

| Packaging | Wooden crates, Bundles with protective caps, Wrapped with plastic film |

| Certifications | ISO 9001, PED, ASME, TUV, Lloyd’s Register |

| Price | Based on material, size, and order quantity; inquire for specific pricing |

| Delivery Time | 15-45 days depending on the order size and specifications |

Product Overview

Heat Exchanger Tubes are critical components used in various industries to transfer heat efficiently between two or more fluids. These tubes are engineered to withstand high pressures and temperatures while providing excellent thermal conductivity and corrosion resistance. Commonly used in systems like HVAC, power generation, and chemical processing, they ensure optimal heat transfer performance and system reliability.

Key Features

- Superior Material Selection: Available in stainless steel, carbon steel, copper, titanium, and nickel alloys, offering excellent thermal and corrosion resistance properties.

- Versatile Applications: Ideal for use in HVAC systems, power plants, chemical processing, oil & gas, marine environments, pharmaceuticals, and food & beverage industries.

- High Durability: Engineered to withstand extreme temperatures, pressures, and corrosive environments, ensuring long-term reliability.

- Precision Manufacturing: Available in both seamless and welded forms, with options for U-bending and finned tubes to enhance heat exchange efficiency.

Application Scenarios

Heat Exchanger Tubes are used in a wide range of applications, from industrial boilers and condensers to refrigeration systems and evaporators. Their role in efficient heat transfer is vital for energy conservation and operational efficiency in various industrial processes.

Quality Assurance

Our Heat Exchanger Tubes undergo rigorous testing, including hydrostatic, eddy current, and ultrasonic tests, to ensure they meet the highest quality standards. Certified to ISO 9001, PED, ASME, TUV, and Lloyd’s Register, our products are trusted globally for their reliability and performance.

Ordering and Inquiries

To ensure you get the most appropriate Heat Exchanger Tube for your needs, please contact our sales team. We provide customized solutions and competitive pricing based on your specific requirements.

Reviews

There are no reviews yet.